How Automation Transforms Paper Core Production Efficiency in 2025 | Elsner Engineering

Paper tube and core manufacturers face mounting pressure to increase production efficiency while simultaneously meeting sustainability requirements and managing rising raw material costs that squeeze profit margins across the industry. Automation technologies provide manufacturers with practical pathways addressing these competing demands through enhanced production speeds, improved quality consistency, reduced material waste, and lower labor requirements that collectively strengthen competitive positioning. The global tubes and cores market growing at 7.1 percent annually through 2029 creates urgent incentives for manufacturers to adopt automation solutions maintaining pace with expanding demand while preserving profitability despite challenging cost structures.

Traditional manual and semi-automated paper tube winding processes limit production throughput, introduce quality variability based on operator skill and fatigue, and generate excessive material waste during startup, changeover, and troubleshooting activities. These limitations become increasingly problematic as customers demand tighter tolerances, faster delivery times, and documented quality systems demonstrating process control and capability. According to industry analysis, manufacturers are increasingly investing in automation and smart technologies to enhance production efficiency and reduce operational costs, with innovations streamlining manufacturing processes while ensuring consistent product quality across evolving industry needs.

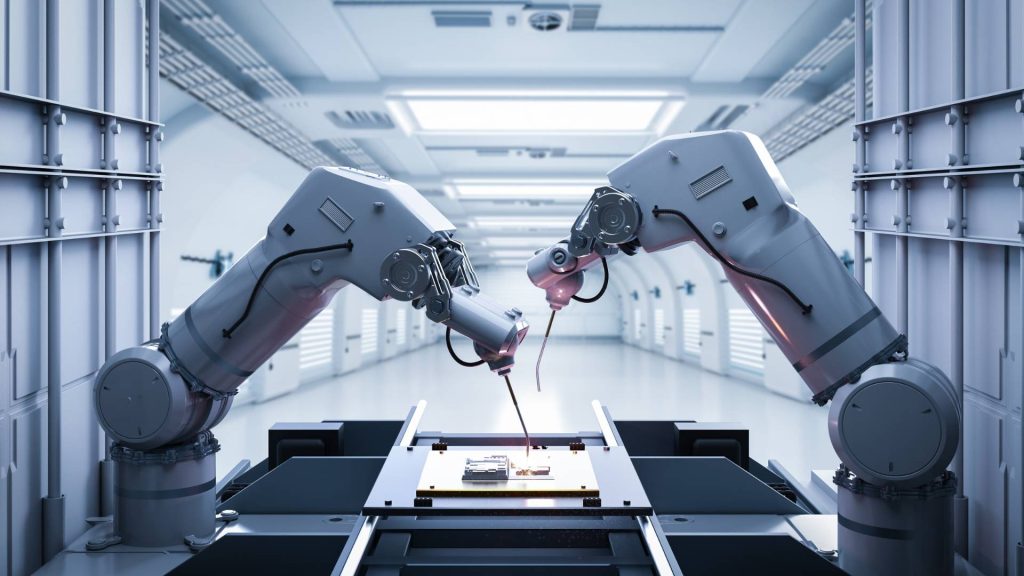

Automation addresses paper tube manufacturing challenges through integrated systems combining precision mechanical components, advanced control software, and real-time monitoring capabilities that optimize production parameters continuously without manual intervention. Modern automated winding lines achieve production rates three to five times faster than manual operations while maintaining dimensional tolerances measured in thousandths of inches across sustained production runs. This performance transformation enables manufacturers to accept larger orders, reduce lead times, and serve demanding applications requiring consistency levels impossible through manual methods regardless of operator skill or experience.

Precision Control Systems Eliminate Production Variability

Automated paper tube winding equipment incorporates servo motor drive systems providing precise control over spindle rotation speeds, traverse movement, and material tensioning that maintain optimal processing conditions throughout production cycles. Unlike manual systems relying on operator judgment and mechanical adjustments, servo-controlled equipment executes programmed winding recipes with exact repeatability producing virtually identical tubes regardless of production timing, operator assignment, or ambient conditions. This consistency proves particularly valuable for manufacturers serving customers with stringent specifications where dimensional variations outside narrow tolerance bands result in product rejection and rework costs.

Electronic tension control systems represent another critical automation component monitoring and adjusting material tension in real-time as winding progresses and spool diameters change. Traditional mechanical tension systems using friction brakes and dancer rollers require frequent manual adjustment and produce variable tension as material properties change with humidity, temperature, and roll age. Electronic systems employing load cells and closed-loop feedback maintain constant tension automatically compensating for these variables without operator intervention. Consistent tension throughout winding prevents defects including loose winds, telescoping, and dimensional variations that compromise tube performance and appearance.

Programmable logic controllers serving as central automation platforms coordinate multiple machine functions ensuring proper sequencing, monitoring safety interlocks, and collecting production data for quality documentation and process optimization. Modern PLCs feature intuitive operator interfaces displaying real-time production status, alarm notifications, and performance metrics that enable quick identification of developing issues before significant production impacts occur. Recipe management systems within PLCs store hundreds of product specifications allowing rapid changeovers between different tube dimensions, materials, and quality requirements with minimal downtime and setup waste.

Material Handling Automation Reduces Labor and Improves Safety

Automated material loading systems eliminate manual handling of heavy paper rolls reducing workplace injury risks while improving production efficiency through consistent material presentation to winding equipment. Robotic roll handling systems equipped with vacuum lifting attachments position supply rolls precisely for automatic splicing and threading, operations historically requiring two workers and creating production bottlenecks during material changeovers. Understanding Sustainable Paper Tube Manufacturing Drives $3.55 Billion Market Growth Through 2029 provides context for how manufacturers balance automation investments against sustainability objectives and market expansion opportunities.

Finished tube unloading automation removes completed products from winding mandrels, transfers them to accumulation conveyors, and organizes them for packaging without manual intervention. Automatic unloading eliminates production pauses waiting for operators to remove finished tubes while preventing tube damage from rough handling during manual unloading operations. Some advanced systems incorporate inline quality inspection during unloading detecting dimensional defects, surface imperfections, and structural issues that trigger automatic rejection before defective products advance to packaging and shipping.

Integrated conveyor systems connect individual process stations creating continuous material flow from raw material storage through finished product packaging. These automated handling networks eliminate manual transfer steps that slow production, risk product damage, and require labor for non-value-added material movement. Conveyor systems incorporate accumulation zones buffering between process stations with different cycle times, preventing production bottlenecks while maintaining continuous equipment operation maximizing utilization of capital-intensive winding equipment.

Real-Time Quality Monitoring Prevents Defect Production

Vision inspection systems integrated into automated winding lines examine tube surfaces during production identifying defects including scratches, contamination, adhesive voids, and fiber orientation issues invisible to operators monitoring equipment from control stations. High-resolution cameras capture multiple images per tube as products pass inspection stations, with image processing software comparing captured images against quality standards identifying deviations triggering automatic alerts or product rejection. This inline inspection approach prevents defective product accumulation enabling immediate process corrections minimizing waste and rework.

Dimensional measurement systems employing laser sensors or mechanical gauges verify tube diameters, wall thicknesses, and lengths throughout production runs documenting compliance with customer specifications. Automated measurement eliminates variability from manual inspection techniques while providing statistical process control data identifying trending issues before specifications are violated. Some systems automatically adjust winding parameters in response to dimensional measurements implementing closed-loop control that maintains targets despite raw material variations or environmental changes affecting production.

Weight monitoring integrated with production counting provides another quality verification layer detecting missing plies, adhesive application problems, or material density variations affecting tube performance. Automatic weight checking at production speeds ensures every tube meets specifications without manual sampling and weighing that checks only small percentages of production volumes. The comprehensive quality data generated by automated inspection systems supports customer quality requirements, ISO certification maintenance, and continuous improvement initiatives identifying opportunities for process optimization.

Energy Efficiency Through Automation Intelligence

Modern automated winding equipment incorporates energy management features substantially reducing electrical consumption compared to legacy mechanical systems. Variable frequency drives powering servo motors adjust speeds precisely to production requirements avoiding energy waste from continuously operating motors running at fixed speeds regardless of actual demand. Regenerative braking systems on high-inertia components capture kinetic energy during deceleration returning power to electrical systems rather than dissipating energy as heat through mechanical brakes.

Intelligent heating systems controlling adhesive application temperatures and material conditioning optimize thermal energy usage through zoned temperature control, insulated components, and automatic setback during idle periods. Some systems incorporate predictive heating algorithms that adjust temperatures based on production schedules ensuring equipment reaches operating temperatures coinciding with production start times eliminating extended warmup periods consuming energy without producing output. These heating optimizations deliver significant energy savings in high-temperature processes like adhesive application where thermal losses historically represented substantial operational costs.

Production scheduling optimization enabled by automation systems reduces equipment idle time and minimizes startup/shutdown cycles that waste energy and generate scrap. Manufacturers program automated lines to sequence production batches minimizing changeovers while maintaining delivery schedules, improving overall equipment effectiveness while reducing per-unit energy consumption. The operational data collected by automation systems enables energy usage analysis identifying specific equipment or processes consuming disproportionate energy relative to production output, guiding targeted efficiency improvement investments.

Integration with Manufacturing Execution Systems

Automation systems connect with enterprise-level manufacturing execution systems providing production visibility, inventory management, and quality traceability throughout manufacturing operations. This integration enables real-time production monitoring from remote locations, automated material requirements planning, and comprehensive quality documentation meeting customer audit requirements without manual record compilation. The digital integration between shop floor automation and business systems eliminates duplicate data entry, reduces administrative labor, and improves information accuracy supporting better management decisions.

Production data automatically collected by automated equipment feeds statistical process control systems tracking performance trends and identifying optimization opportunities. Analysis of historical production data reveals patterns correlating material properties, environmental conditions, or equipment settings with quality results enabling proactive adjustments preventing defects rather than detecting them post-production. Machine learning algorithms analyze vast data sets identifying subtle relationships that human analysis might overlook, suggesting process improvements that automated systems can test and implement without manual programming.

Examining E-Commerce Boom Reshapes Paper Tube Manufacturing Equipment Demand reveals how automation capabilities must address evolving customer requirements driven by online retail packaging needs and rapid delivery expectations. Manufacturers serving e-commerce markets require flexible automation accommodating frequent product changes, small batch production, and just-in-time delivery schedules impossible through rigid manual production systems.

Workforce Implications and Skills Development

Automation transforms workforce requirements in paper tube manufacturing from primarily manual labor performing repetitive winding operations to skilled technicians monitoring automated systems, performing preventive maintenance, and optimizing production parameters. This skills transition creates challenges for manufacturers employing workforces trained in manual operations but offers opportunities for employees seeking more technical roles with higher compensation and better working conditions. Progressive manufacturers implement training programs developing automation operation, troubleshooting, and programming skills within existing workforces rather than replacing experienced employees with new hires.

The improved workplace safety resulting from automation significantly reduces injury risks associated with repetitive motions, heavy lifting, and proximity to moving machinery that characterize manual winding operations. Automated systems incorporate comprehensive safety guarding, emergency stop systems, and lockout/tagout capabilities protecting workers while maintaining productivity levels impossible with extensive manual safety controls. Lower injury rates reduce workers compensation costs, improve employee morale, and enhance manufacturer reputations as safe employers in competitive labor markets.

Automation enables manufacturers to maintain production despite workforce shortages affecting many industries as demographic shifts reduce available labor pools. Automated lines operate with minimal supervision producing consistent output despite difficulty recruiting and retaining production workers in tight labor markets. This operational resilience provides strategic advantage allowing manufacturers to accept orders competitors cannot fulfill due to staffing constraints while avoiding premium wages and signing bonuses required attracting workers to manual production positions.

Return on Investment Considerations

Automation equipment requires substantial capital investment that manufacturers must justify through detailed return on investment analysis considering equipment costs, installation expenses, training requirements, and ongoing maintenance against projected savings from increased productivity, quality improvements, and reduced labor. Payback periods for paper tube winding automation typically range from eighteen months to four years depending on production volumes, product mix complexity, labor rates, and quality improvement benefits. Higher-volume operations producing standard products achieve faster payback through greater utilization of automation capabilities while lower-volume custom manufacturers face longer payback periods but still benefit from quality consistency and flexibility advantages.

Financing options including equipment leasing, manufacturer payment plans, and government incentive programs reduce upfront capital requirements making automation accessible to manufacturers unable to fund complete system purchases from operating cash flow. Some equipment suppliers offer performance-based payment structures linking payments to achieved productivity improvements or quality metrics aligning supplier and customer interests while reducing manufacturer implementation risks. These creative financing approaches accelerate automation adoption throughout the industry particularly among smaller manufacturers historically disadvantaged by limited capital access.

The competitive dynamics within paper tube markets increasingly favor automated manufacturers capable of meeting demanding customer requirements for quality consistency, delivery reliability, and documented process control. Manufacturers delaying automation risk losing customers to competitors offering superior service enabled by modern production capabilities. This competitive pressure combined with demonstrable financial returns creates compelling business cases for automation investment even in capital-constrained environments where alternative investments compete for limited resources.

Elsner Engineering: Automation Solutions for Paper Tube Manufacturing

Elsner Engineering Works designs and manufactures precision winding equipment incorporating automation technologies that enhance paper tube production efficiency while maintaining the flexibility required for diverse product ranges. Our Paco Winders product line features advanced control systems, automated material handling, and integrated quality monitoring delivering productivity improvements and consistency manufacturers require in competitive markets.

With nearly a century of manufacturing experience and deep expertise in converting machinery, Elsner understands the practical requirements of production environments where equipment must deliver reliable performance across multiple shifts and product changeovers. Our equipment incorporates industrial-grade components, intuitive operator interfaces, and comprehensive documentation supporting long-term operational success.

Our Capabilities Include:

Paco Winders - Advanced winding systems featuring automated controls, precision tensioning, and quality monitoring for efficient paper tube production

Contact Elsner Engineering - Discuss automation solutions matching your production requirements and improvement objectives

Ready to Transform Your Production? Contact Elsner Engineering to explore how automated winding equipment can enhance your paper tube manufacturing efficiency, quality, and competitiveness.