Paco Winders

Paco Winders

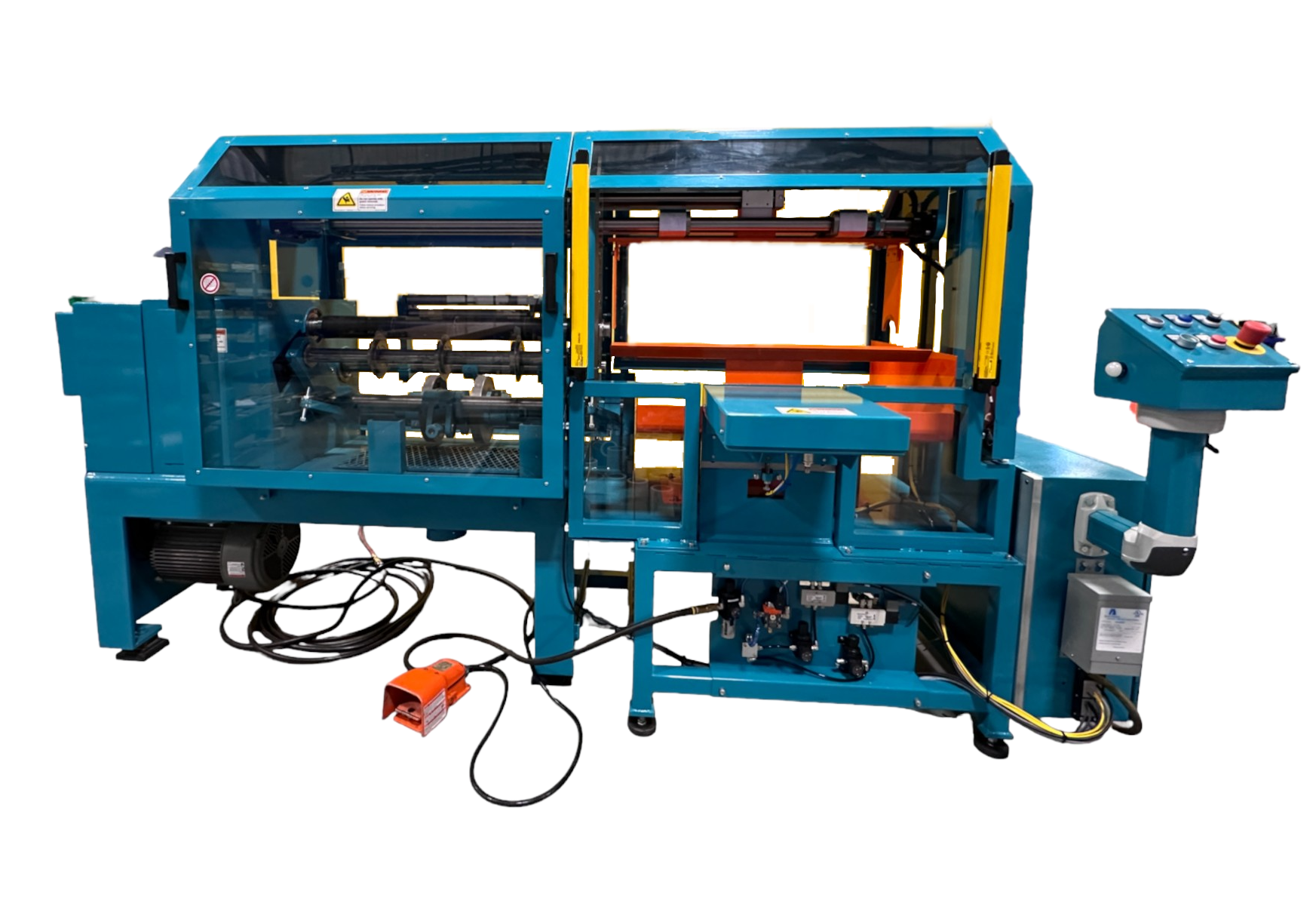

Elsner offers precision Paco Winders engineered for high-quality turnkey paper tube and core production. Our machines support comprehensive web slitting, winding, and lamination processes, delivering exceptional quality for core manufacturers across the globe. Built with dependable components and featuring consistent tension control, Paco Winders create products that meet exact specifications.

Contact us at (717) 637-5991 to discuss your tube and core production needs

Start Your Paco Winder Project

From initial inquiry to production implementation, our team provides the expertise you need to select and implement the right winding solution.

Phone: (717) 637-5991 Email: eew@elsnereng.com

Precision Winding Technology

Our Paco Winders incorporate advanced features for optimal tube and core production:

- Accurate Web Tensioning: Consistent material control throughout the winding process

- Precision Slitting Systems: Clean cuts with minimal dust and perfect alignment

- Controlled Adhesive Application: Uniform glue distribution for secure lamination

- Variable Speed Operation: Adjustable production rates to match your requirements

- Automatic Core Ejection: Smooth removal of finished products

- Quick Changeover Design: Minimal downtime between production runs

These capabilities combine to create a winding system that produces high-quality tubes and cores with excellent dimensional stability and structural integrity.

Core Production Applications

Our Paco Winders excel in creating cores and tubes for multiple industries:

- Paper Converting: Cores for tissue, towel, and specialty paper rolls

- Film Production: Support cores for plastic film and flexible packaging

- Textile Industry: Fabric and yarn winding cores

- Industrial Applications: Heavy-duty cores for construction materials

- Shipping & Storage: Protective tubes for document and material transportation

- Specialty Products: Custom cores for unique applications

Each application benefits from the consistent quality and dimensional accuracy that our Paco Winders provide.

Discuss your specific core production applications with our team

Paco Winder Models

We offer multiple Paco Winder models to match your production requirements:

- Spiral Winders MW Series: Precision winding systems for spiral-wound tube and core production

- Convolute Winders C-Series:Specialized winders for convolute-style tube manufacturing

- Automatic Tube Recutters AR Series: Efficient systems for precise cutting of finished tubes

- Cut-off Saws: Complementary equipment for tube and core finishing operations

Each model features rugged construction, precise controls, and proven reliability to maximize production uptime and product quality. All Paco Winders are now manufactured to ELSNER's rigorous standards since our acquisition of Paco Winders from OX Industries.

Contact us to discuss your exact application and determine the ideal model for your needs!

Contact us to determine the ideal configuration for your needs

Production Advantages

Investing in an Elsner Paco Winder delivers significant production benefits:

- Consistent Product Quality: Uniform cores that meet exact specifications

- Reduced Material Waste: Precise controls minimize scrap generation

- Lower Labor Requirements: Automated operation reduces staffing needs

- Increased Production Rates: Optimized processes maximize output

- Improved Workplace Safety: Modern guarding and control systems

- Extended Equipment Lifespan: Durable construction for decades of service

These advantages create an exceptional return on investment for tube and core manufacturers focused on quality and efficiency.

Global Service & Support

We support our Paco Winders wherever they operate around the world:

- Installation Assistance: Professional setup and commissioning

- Operator Training: Comprehensive instruction for your production team

- Technical Support: Expert help when you need it

- Spare Parts Inventory: Critical components ready for immediate shipment

- Preventive Maintenance Programs: Scheduled service to prevent downtime

- Machine Upgrades: Options to improve capabilities as needs evolve

This commitment to service creates peace of mind for manufacturers who depend on our equipment for daily production.

The Elsner Manufacturing Difference

Our approach to manufacturing Paco Winders reflects our company values:

- Engineering Excellence: Thoughtful design focused on practical results

- Quality Construction: Premium materials and expert craftsmanship

- Customer Partnership: Collaborative approach to meeting your needs

- Production Experience: Practical knowledge from decades in manufacturing

- Continuous Improvement: Ongoing refinement of proven designs

- American Manufacturing: Built in our Hanover, PA facility

These principles create winding equipment that consistently meets the challenges of demanding production environments.

Quality Construction Elements

Our Paco Winders feature premium components for long-term reliability:

- Robust Steel Frame: Minimal vibration during operation

- Precision-Machined Components: Consistent performance over decades

- High-Quality Bearings: Smooth operation with minimal maintenance

- Industrial-Grade Electronics: Reliable controls with intuitive interfaces

- Premium Drive Systems: Accurate speed and tension management

- Safety Interlocks: Operator protection with production efficiency

This commitment to quality construction creates machines that maintain performance year after year, even in demanding production environments.

Schedule a manufacturing facility tour to see our quality standards

Request Paco Winder Information

Take the next step toward production excellence. Contact us today to discuss how our Paco Winders can improve your tube and core manufacturing quality and efficiency.

Frequently Asked Questions

Our clients commonly ask these questions about our Paco Winders.

For additional information, please contact our sales or technical teams directly.

Elsner is the owner and manufacturer of Paco Winders. As a division of Elsner Engineering Works, Inc., Paco Winders benefit from our nearly century-long manufacturing heritage and engineering expertise. All Paco Winders are designed, built, and supported directly by Elsner at our Hanover, PA facility, ensuring the same quality standards and customer service that have defined our company since 1934. This integration allows us to provide comprehensive support throughout the entire lifecycle of your Paco Winder equipment, from initial design consultation through long-term maintenance and upgrades.

Our Paco Winders operate at various speeds depending on the model and core specifications. The PW-1000 series typically runs at 30-50 cores per minute for standard sizes, with the PW-2000 reaching 60-80 cores per minute in optimal conditions. Production rates vary based on core diameter, wall thickness, and material composition. During consultation, we analyze your specific product requirements and provide detailed production estimates. We can conduct timed production trials with your materials to verify achievable rates for your particular application.

Our standard Paco Winder lineup accommodates cores ranging from 1" to 12" in diameter (25mm to 300mm) with wall thicknesses from 0.040" to 0.500" (1mm to 12.7mm). Length capabilities span from 2" to 120" (50mm to 3000mm) depending on the model. For requirements outside these parameters, our engineering team can develop custom configurations. We carefully evaluate your product specifications to recommend the most appropriate machine model and setup for your production needs. Each configuration includes the appropriate tooling and adjustments to optimize production for your specific core dimensions.

Floor space requirements vary by model. The PW-1000 typically needs approximately 15' × 20' (4.5m × 6m) of floor space, including operator work areas and material handling. The PW-2000 requires about 20' × 25' (6m × 7.5m), and the PW-3000 multi-station system needs approximately 25' × 35' (7.5m × 10.5m). These dimensions include space for material loading, finished product removal, and operator zones. During the planning phase, our team provides detailed layout drawings to help you prepare your facility. We can adapt configurations to work within existing space constraints when needed.

Our Paco Winders process a wide range of materials including kraft paper (from 18# to 90#), chipboard, specialty papers, and selected non-paper materials. The machines handle single-ply construction or multi-ply laminations depending on your product requirements. For specialty applications, we can configure systems to work with film laminates, foils, and composite materials. Before finalizing equipment specifications, we can conduct material testing to verify compatibility and performance. Our applications team helps determine the optimal material specifications for your particular core products.

Our Paco Winders are designed for minimal maintenance requirements. Routine maintenance includes daily cleaning of adhesive systems, weekly lubrication of specified points, monthly inspection of drive components, and quarterly verification of alignment and calibration. Typical wear items include slitting blades, drive belts, and adhesive application components, which can be replaced during scheduled maintenance to prevent unexpected downtime. We provide comprehensive maintenance documentation with each machine and offer preventive maintenance programs that include regular inspections and scheduled wear part replacement to maximize production uptime and equipment lifespan.